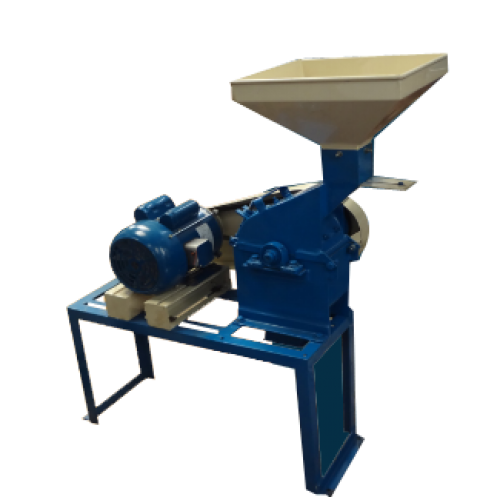

Operating Principle of Gravity Hammer Mill

The materials to be ground into the crushing chamber of hammer mill from feed hopper by gravity or through an auto feeder (optional) the beaters / blades inside the crushing chamber accelerate the material to a very high speed to the toothed liner placed at the upper half of the crushing chamber. Shearing pulverizes the material. The ground materials continuously discharge through screens placed at the bottom periphery of the crushing chamber and excess air filtered through a cotton balloon. Particle size varied using screens with different size holes.

Typical Application of Gravity Hammer Mill

Hammer Mills are exclusively meant for the grinding of sugar, bangle grams, maize, pulses, et cetera

Outstanding Features of Gravity Hammer Mill

- Easy to change screens in a variety of sizes

- Four-way reversible hammers / blades

- Hinged door for easy access to hammer mill interior

- Cold & silent running

- Dust free operations

- Robust Construction

- Low Specific Power Consumption

- Durable Long Life

- Low Temperature Rise for Heat Sensitive Materials

Standard Accessories of Gravity Hammer Mill

- Motor Pulley

- 1 Number cotton balloon

- Anti-vibrating foundation Stand with adjustable rail for motor

- 3 numbers of perforated round hole screens

Extra Accessories of Gravity Hammer Mill

- Suitable totally enclosed fan cooled single/three phase squirrel cage motor {Electricity (Special power can be accommodated): 110/220/380/415 Volts, 50/60 Hz, 1/3 Phase }

- Starters, main switch, ampere meter, capacitor for three phase or Miniature Circuit Breaker, ampere meter, for single phase

- Foundation bolts

- V Belts

- All contacting parts stainless steel 304 / 316 can be accommodated