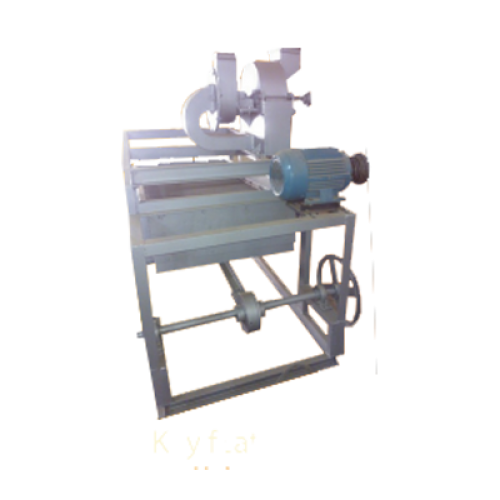

Key features of dalia making machine

- Unique and reliable design of the dalia making plants series pulverizers are highly effective as well as nonstop continuous pulverizing process

- Due to eccentric vibratory screen 3 grades are seprated automaticaly

- All contacting parts are non corrosive materials

- Low temperature grinding technology thus the original ingredient cannot destroy

- Increased production leading to faster return on the investments

- Hardened and fully machined shelving type beater thus less wear and tear

Operating principle of dalia making plant

The flow of material from the feeding hopper is regulating by means of side handle easily to suit the load. Rotor runs in anti-clockwise direction. The beater pass just beneath the ratchet teeth liner fitted inside the top half of the crushing chamber, leaving a suitable gap between the liner teeth and the tips of the rotating beater. This cuts the material caught between the liner teeth like a sword with a scissors action at a 650/1000 RPM. After the required size reduction, the material will pass through the screen fitted inside the lower discharge end of the grinding chamber, the appropriate size screen fitted will not allow coarser material to pass through. The air generated in the crushing chamber forces the powder & broken peaces to pass through the screen fitted at the bottom discharge end of the crushing chamber, into a filter attached to the delivery trough below. Due to low density of powder form it will be suck by blower and collected in bag by cyclone. Broken will seprated by The vibrations are inducing by a cam-operated link.

Servicing guidelines of dalia making plant

Open the cover of chamber all grinding parts cleaned with a brush in couple of minute and the pulverizer is ready for next grinding. If required, the grinding chamber can also washed with water. Remove the cotton balloon and the screen, close the cover tightly and start the grinder. Now pour a bucket or two of water into the hopper. The grinding parts will be flushed with the water and cleaned. Continue running the machine for a few more minutes as the draft of the fresh air sucked into the grinder will dry it. Please check the oil level of oil bath chamber regularly.

Standard accessories of dalia making plant

- Three set of perforated round holes screens for crusher and 2 numbers of screen of vibratory screen

- Motor pulley

- One numbers of cotton balloon

- Mid steel fabricated foundation plate with adjustable rail for motor