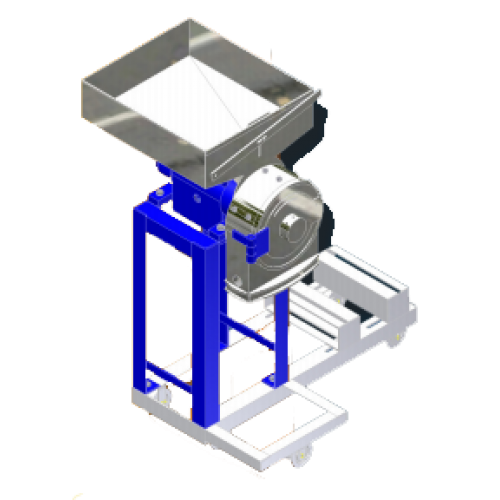

Construction of mini pulverizer

Main body & frame is made of high quality cast iron / M. S. frame, liner of high grade steel casting and bearings are lubricated oil (company supplying the machine without oil) Instead of rubber oil seals metal seals are used for avoiding friction & maintenance, which will occur due to the use of rubber seals.

Operating Principal of mini Pulverizer

The flow of material from the feeding hopper is regulating by means of side handle easily to suit the load. Rotor with four cutters runs in anti-clockwise direction. The beaters pass just beneath the ratchet teeth liner fitted inside the top half of the crushing chamber, leaving a gap of 3 mm between the liner teeth and the tips of the rotating beaters. This cuts the material caught between the liner teeth like a sword with a scissors action at a high speed rotations. After the required size reduction, the material will pass through the screen fitted inside the lower discharge end of the pulverizing chamber. No sieving is required, as the appropriate size screen fitted will not allow coarser material to pass through. The air generated in the crushing chamber forces the powder to pass through the screen fitted at the bottom discharge end of the crushing chamber, into a filter attached to the delivery trough below. (When crushing Wet-Pulpy materials, the balloon should not be use)

Servicing guidelines of mini pulverizer

Open the cover of chamber all pulverizing parts cleaned with a brush in couple of minute and the Pulverizer is ready for next crushing. If required, the grinding chamber can also be wash with water. Remove the cotton balloon and the screen, close the cover tightly and start the grinder. Now pour a bucket or two of water into the hopper. The grinding parts will be flushed with the water and cleaned. Continue running the machine for a few more minutes as the draft of the fresh air sucked into the grinder will dry it. The beater when worm out removed and reserved by removing the cur clip lock holding to the rotor pins. When both the edges are worm out, they sharpened on an emery stone, to be use as new. In addition, when completely warn out, replaced the equal weight and refitted.

Typical Application of mini pulverizer

The Techno Wings mini pulverizers are widely used for grinding of both dry/wet spices, green chilly, fresh ginger, garlic, fresh fruits, vegetables. These pulverizer machine can also be used as a fruit finisher. The techno wings Mini Pulverizer can also be used for the following dry applications like agricultural chemicals, broken biscuits, custard powder, coffee, charcoal, dals, dyes & pigments, fillers, henna leaves, herbs, leaves and roots instant foods insecticides and pesticides, kaolin molding powders, pharmaceuticals, plastics, poultry feed & marine feed, resins, sugar (biscuit grade/icing grade), Stearates, tea etc

Outstanding Features of mini pulverizer

- Unique and Reliable Design

- The mini series pulverizers are highly effective as well as non stop continuous pulverizing process

- Compact size

- Interchangeable & reversible joint less hardened beater thus, the pulveriser will last a life time with minimum replacements

- Dust free operation

- Grinding is carried out in a cool atmospheric temperature, which guarantee against thermal degradation of product quality and flavors