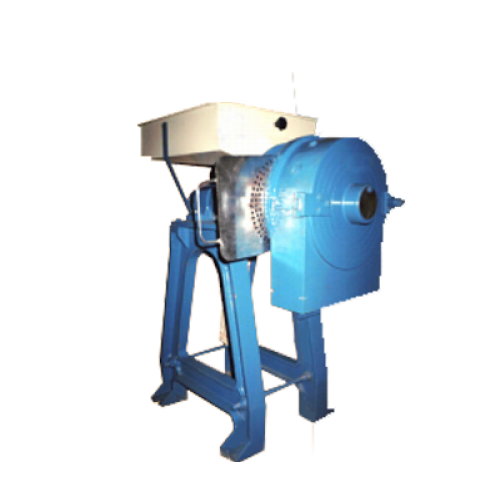

About double stage pulverizer

Techno wings double stage mills are the latest version of the Techno wings mini pulverizer. It is provided with a pre-crushing chamber where the material undergoes a coarse grinding and passes on to the fine powdering chamber. So we can feed the hard materials like turmeric directly for fine Grinding in single feeding. This also gives more evenness for the spices powder. The operational life of the screens (sieves) in a double stage mill is about 20 times that of standard mini pulverizer of the same capacity.

Construction of double stage pulverizer

Pre crushing chamber is fixed on the hinges, which also act as door for fine crushing chamber. The center classifier sieve also can be taken out very easily by twisting from the lock bolts. The feeding of this pulverizer is through the top center of the back end. The Crushing chamber and bearing blocks are made from high quality cast iron. Deep groove single raw bearing are lubricated in oil. The crushing chamber, base of double stage pulverizer and bearing blocks are made of high quality cast iron. But for model no TW-84 base of pulverizing machine is made of mild steel “C” section and for TW-168 the crushing chamber, base of pulverizing machine are made of heavy duty mild steel. Tw-168 is supplied with extra third self align bearing pedestal. Bearing are lubricated in oil. For heavy duty double stage mills, oil window is provided for bearing blocks. Water jacket is a optional provision for all double stage mills the machine is supplied with air filter and cotton balloon.

Operating principal of double state pulverizer

The flow of material from feeding hopper is regulated means of a vertical adjustable slide suit the load indicated by the ampere meter. The rotor and beater are mounted on shaft, running in ball bearing housing at a speed of 4500- 6000 RPM first chamber having rotor with four beater funs in anti clockwise direction. The beater pass just beneath the “V” shaped teeth liner fitted inside the crushing chamber, leaving a gap of 3 mm between the liner teeth and the tips of the rotating beater. This cuts the material caught between the liner teeth like a sword with a scissors action at a high speed. After getting recoverable mesh crushed material is enter in to final stage of crushing chamber, is inlaid with a delivery trough attached at the bottom, with a delivery trough attached at the discharged end.

Servicing guidelines of double stage pulverizer

Open the cover of chamber all grinding parts cleaned with a brush in couple of minute and the pulverizer is ready for next crushing. If required, the grinding chamber can also be washed with water. Remove the cotton balloon and the screen, close the cover tightly and start the grinder. Now pour a bucket or two of water into the hopper. The grinding parts will be flushed with the water and cleaned. Continue running the machine for a few more minutes as the draft of the fresh air sucked into the grinder will dry it. The beater when worm out removed and reserved byremoving the cur clip lock holding to the rotor pins. When both the edges are worm out, they are sharpened on an emery stone, to be used as new.

Typical application of double stage pulverizer

The jas double chamber pulverizer can be used for a wide range of application e.g. Grinding spices, food stuffs, chemicals, pigments, pharmaceuticals, herbals, coffee seeds, tea leaves, fillers, sugar, etc.,

Outstanding features of double stage pulverizer

- Unique and reliable design

- The double stage pulverizer series machines are highly effective as well as nonstop continuous pulverizing process.

- Compact size

- Dust free operation

- Ideal for dry crushing Increased production leading to faster return on the investments

- Rail for motor adjustment Low temperature rise for heat sensitive materials.