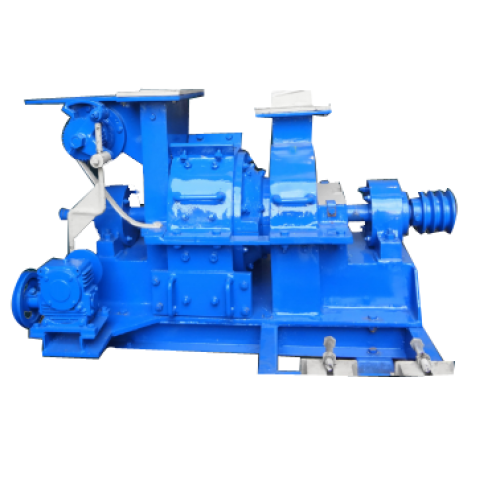

Construction of Impact Pulverizer:-

- Type: Air Swept Impact Mill with Whizzier Classifier operation in closed circuit

- Body: Solid iron, machined and aligned on a strong iron base with top covers bolted.

- Feeder: Automatic Rotary Feeder, gear driven from the main shaft with feed control mechanism

- Crushing Chamber: Lined with renewable solid iron ( Stainless steel optional) breaker plates

- Rotor: Machined mild steel thick plates mounted on main shaft

- Shaft: Solid Alloy Steel

- Classifier: Mild Steel whizzier Classifier with adjustable spider to control fineness of ground powder up to 300 mesh depending on the type of material being pulverized

- Bearings: self-aligning ball bearings in cast iron housing with suitable grease cups for lubrication

- Hammers: Forged alloy steel, hard faced, with manganese steel electrodes and balanced.

- Blower: Paddle type with replaceable blades

- Cyclone: Mild Steel sheet fabricated

- Dust Collector: Top and Bottom halves of Mild Steel Sheet, to be interconnected by dust bags

- Piping: All interconnecting Mild Steel piping supplied with loose flanges to facilitate easy erection

Standard Accessories of Impact pulverizer:-

- Motor pulley

- 2 Number cotton balloons.

- Anti vibrating foundation stand with adjustable rail for motor

Extra Accessories of Impact pulverizer:-

- Suitable totally enclosed fan cooled three phase squirrel cage motor as per is: 325. {Electricity (special power can be accommodated): 110/220/380/415 volts, 50/60 Hz, 1/3 phase}

- Starters, main switch, ampere meter, capacitor for three phases

- Foundation bolts

- V Belts

- All Contacting Parts Stainless Steel 304 / 316 can be accommodated